Kingston University produces most powerful student-built rocket in the UK

By Oliver Monk 14th May 2024

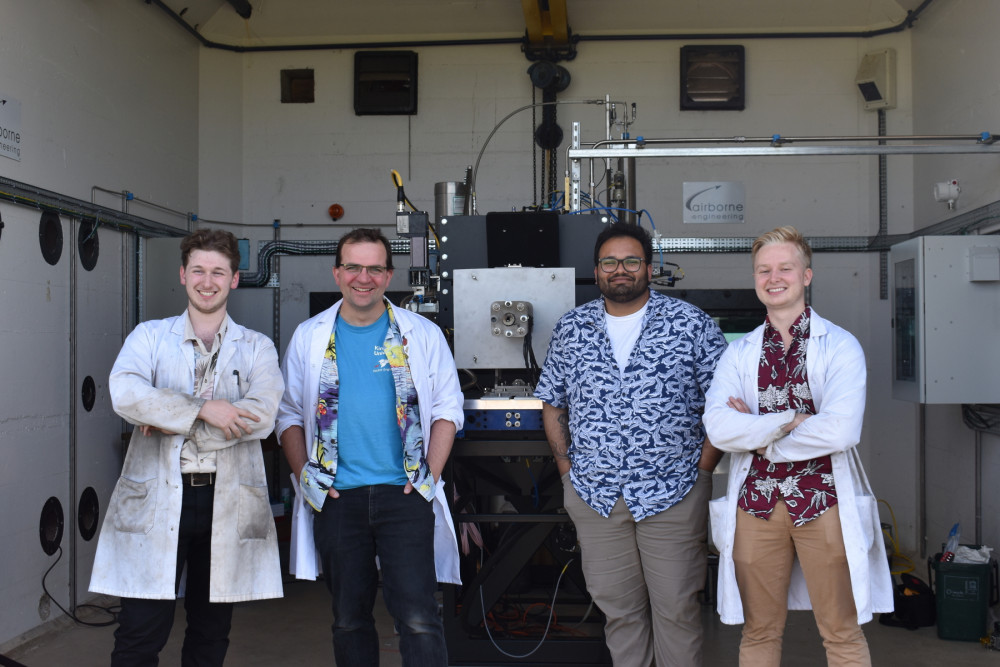

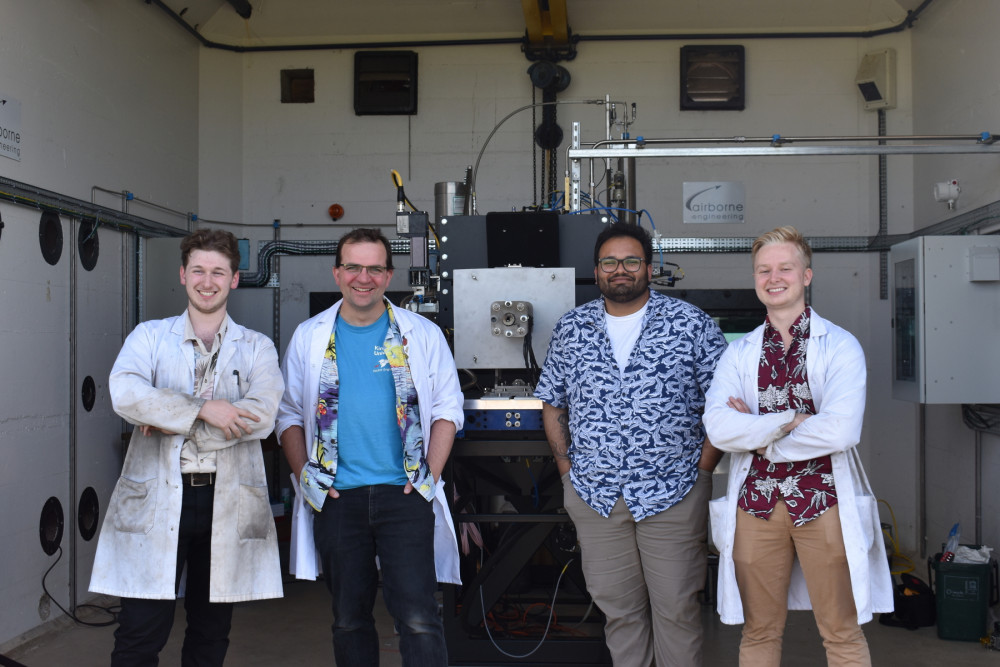

The Kingston University Rocket Engineering team (KURE) is building the most powerful 3D printed rocket engine ever produced by students in the UK.

The 3D printed rocket engine is being built as part of the National Propulsion Competition, where teams of students from across the country compete to see who can build the most successful rocket engine.

The competition forms part of the Race to Space initiative, led by the University of Sheffield, which aims to provide the UK space sector with the better trained, better prepared graduates it needs to continue its ambitious growth.

Talking about the team's entry into the competition Vinay Williams, the team's systems engineer and second year doctorate student at Kingston University, said they had ambitious plans for the future.

"Our engine is going to be a big improvement on last year's and we hope for it to be the powerhouse for our space shot within the next five years," he said.

"We took a lot from last year's competition, with Rolls Royce being impressed with our engine as well as a number of industry experts."

The competition is judged by prominent figures from the engineering industry including the likes of Rolls Royce, McLaren and the Alpine F1 team.

The team has ambitious plans for the future and aim to compete in the Spaceport America Cup – the biggest student rocket competition in the world – in the future.

Next year, the team also wants to conduct a full launchpad test which would bring them one significant step closer to launching into space.

As part of the competition's requirements the team have also been involved in some important outreach work. This has included visiting local primary schools, such as Knollmead in Worcester Park, and running sessions with the children to help make and launch their own water bottle rockets.

The team's project manager, aerospace engineering master's student Mathias Welher, has credited the university's new rocket lab, unveiled last year, with helping the students plan and test their designs more thoroughly.

Senior aerospace engineering lecturer Dr Peter Shaw said: "This student-led project has been a massive confidence booster to our students developing industrial relevant skills as part of the Kingston University future workforce strategy," he said.

"If successful, the engine will be the most powerful student built and test fired rocket engine in the UK. It is part of our engine development program to build a sub-orbital rocket that will propel our students work, dedication, effort and dreams literally into Space."

The team are now continuing their preparations ahead of the National Propulsion Competition where the team will compete in a variety of categories including best engine and best team.

CHECK OUT OUR Jobs Section HERE!

kingston vacancies updated hourly!

Click here to see more: kingston jobs

Share: